Liquids

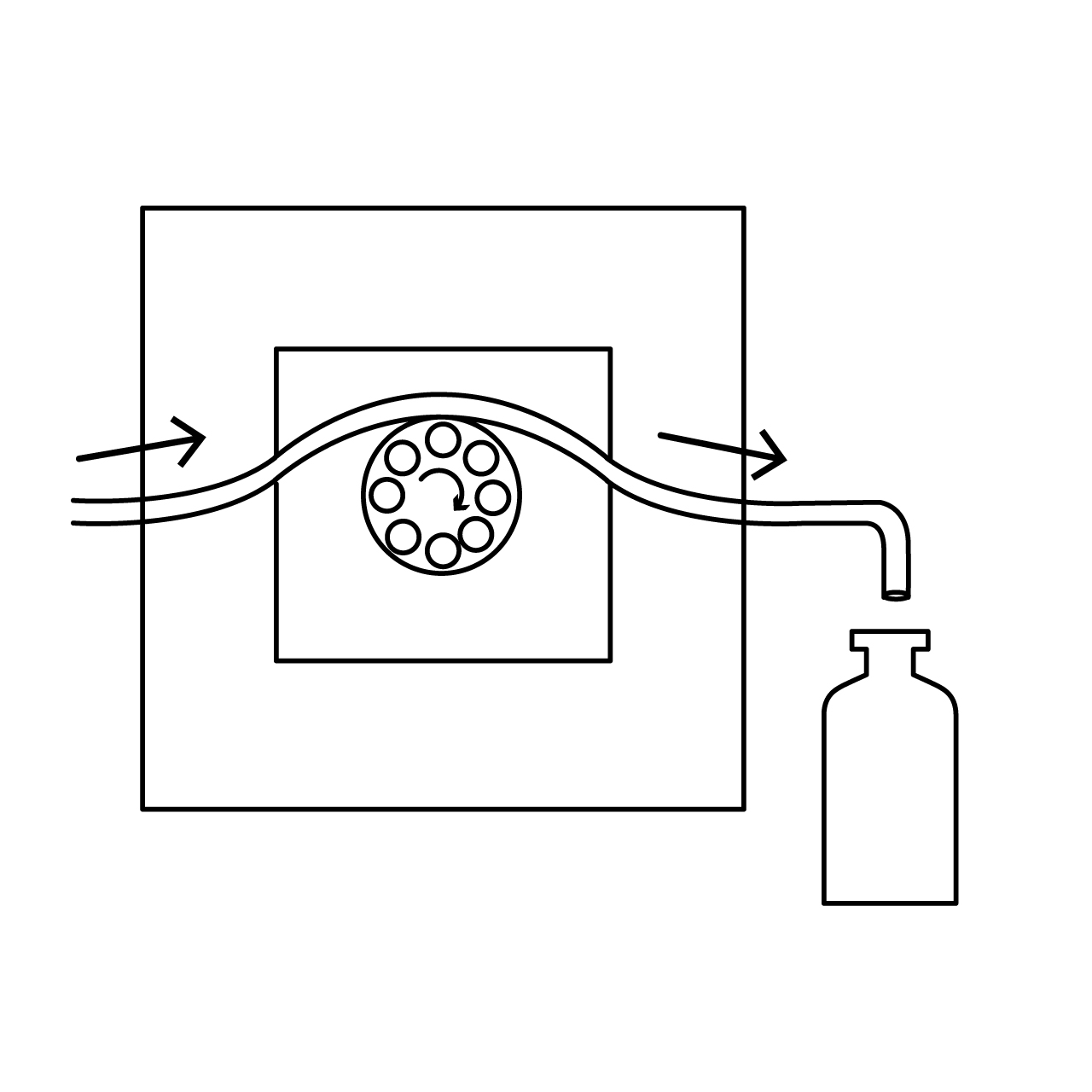

Peristaltic filling

The great advantage of peristaltic filling is that the pump is never in contact with the product. For cleaning purposes, the tubes are changed. No valves or mechanical parts need to be cleaned.

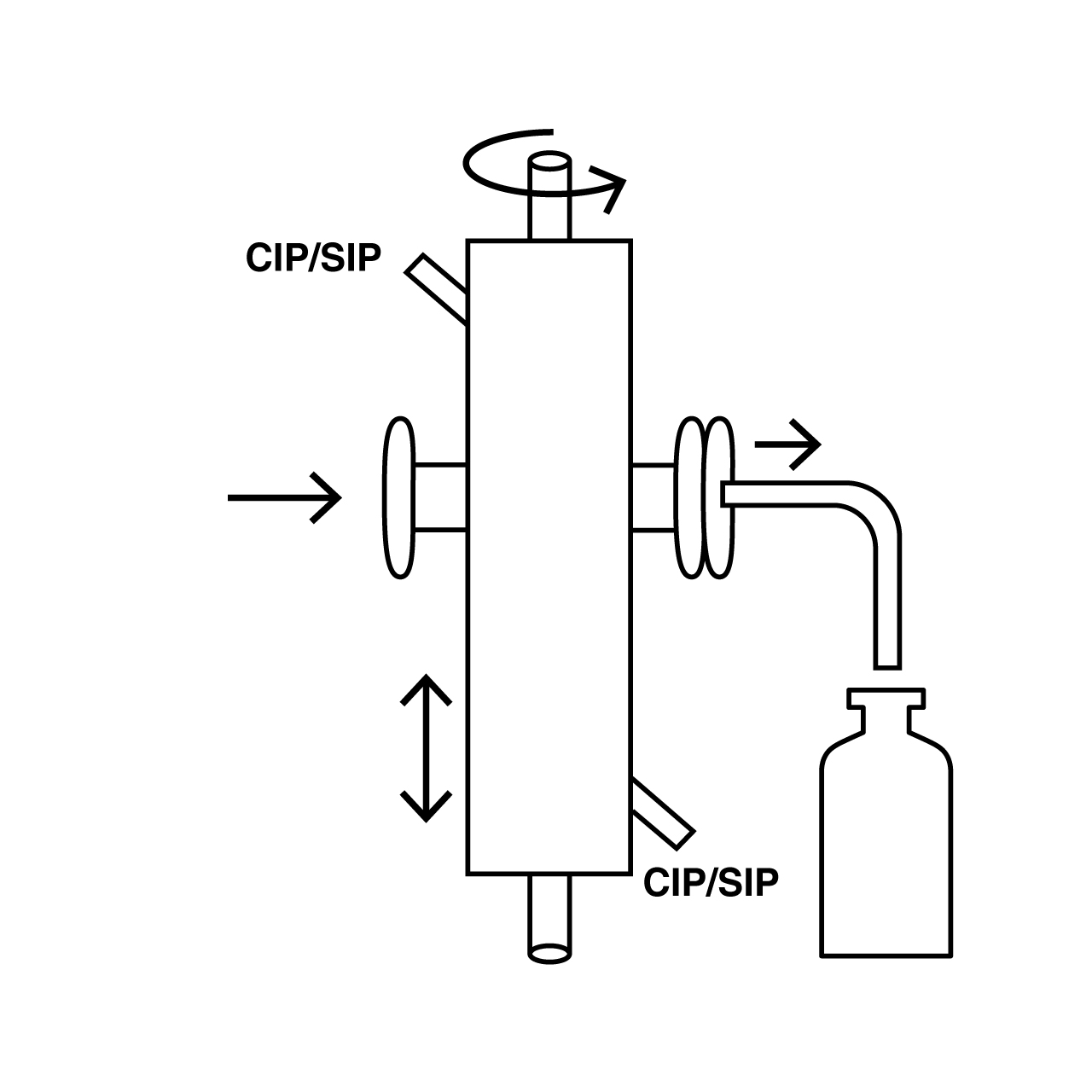

Turn piston filling

Sealless turn piston pumps are widespread in pharmaceutical and diagnostic industry. They are made-to-measure and are manufactured in a single-block procedure in 316L stainless steel that meets the requirements of the pharmaceutical industry. A hard chrome and CrN PVD coating leads to maximum mechanical resilience. We offer Cleaning In Place – Sterilisation In Place (CIP-SIP) versions. All pumps are manufactured according to Good Manufacturing Practice (GMP) and undergo an hermeticity test before shipping (Flotest®).

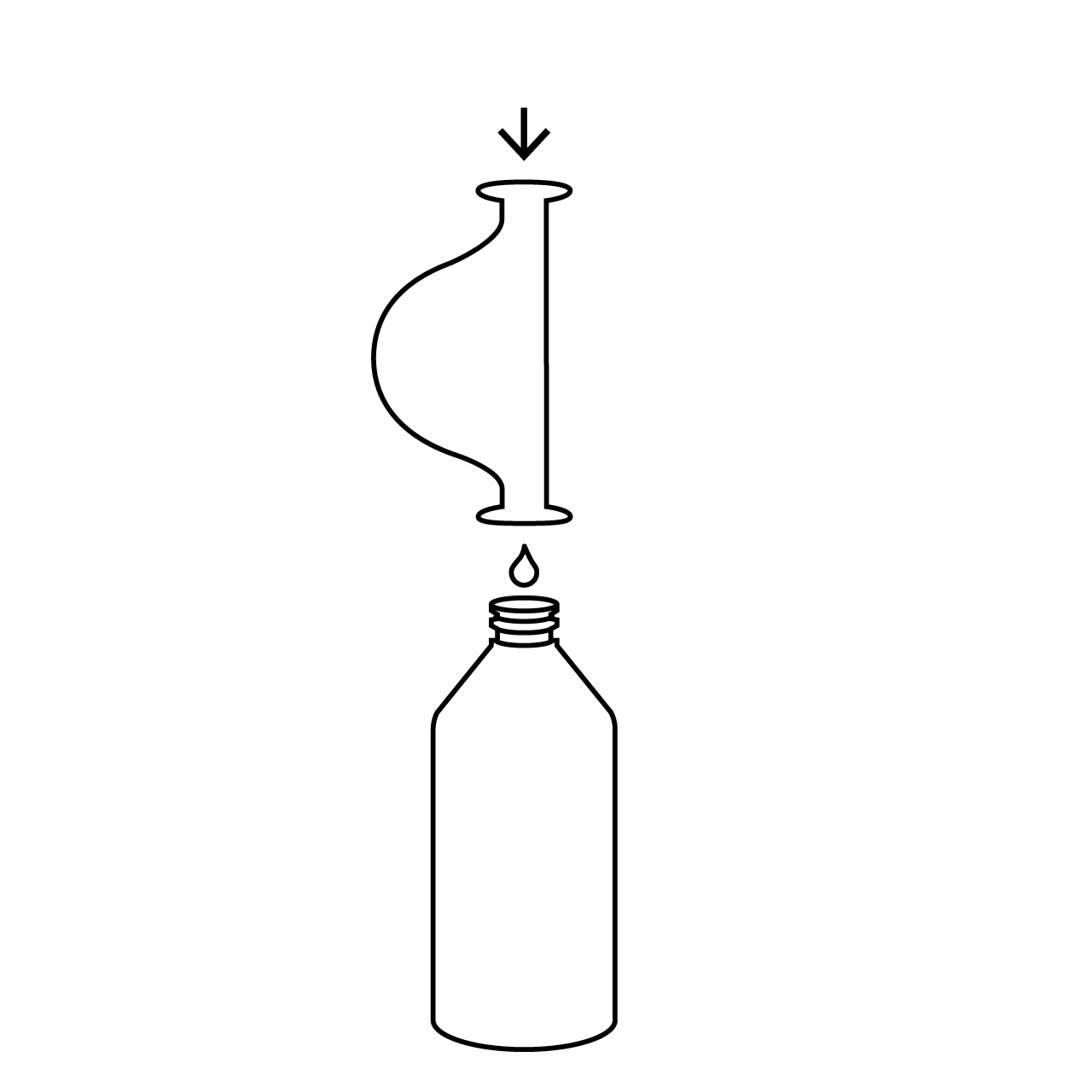

Mass flow measuring Coriolis

Suitable for dosing within an aseptic environment as cleaning and sanitation/sterilization can be done in place (CIP/ SIP). Apart from that, no format parts, as e.g. pistons, are needed to dose different volumes.