Transport

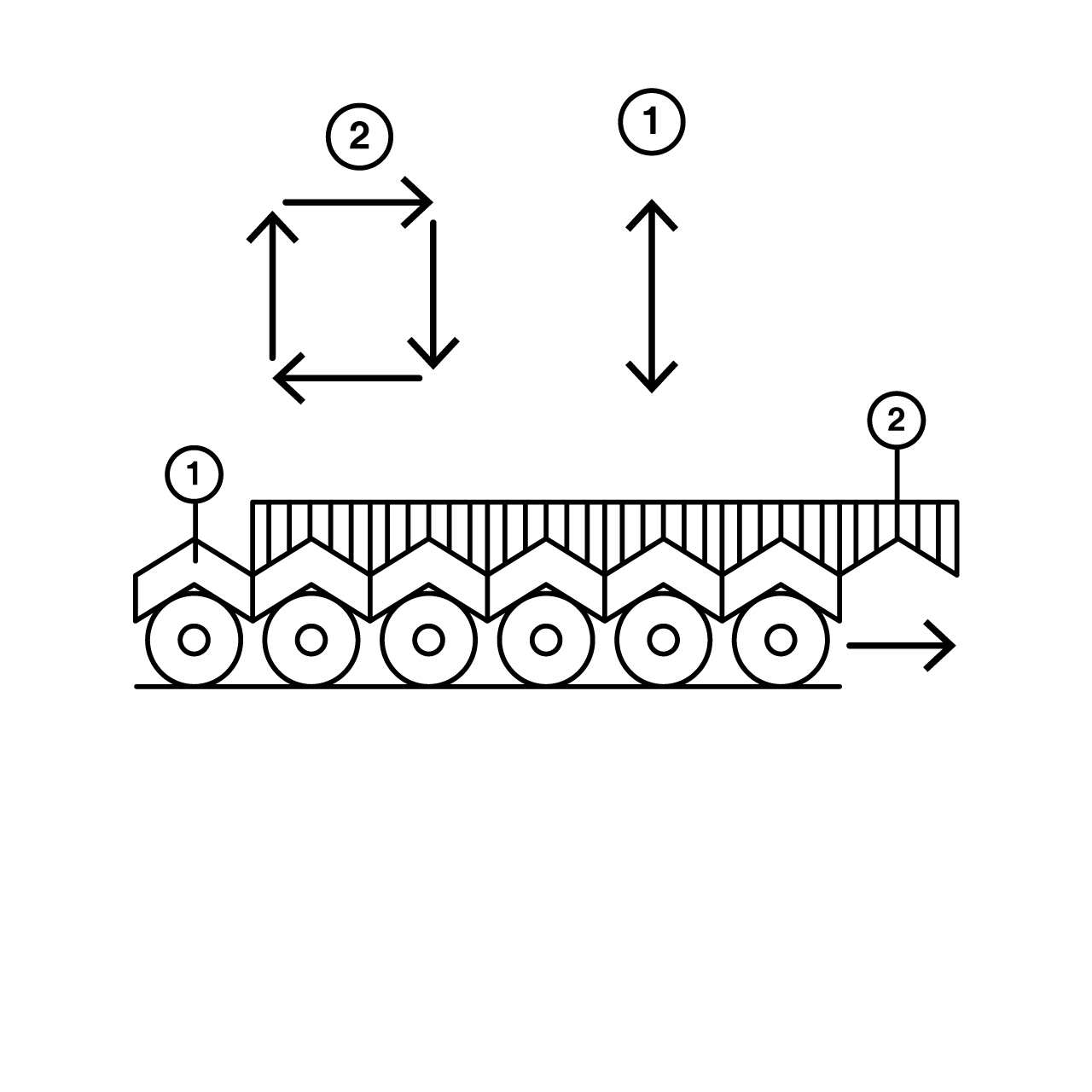

Single walking beam

Round, square or oval containers are moved by a transport bar making a walking beam movement. This system enables a format part free transport of stable containers with diameters between 16 – 100 mm. Mechanical settings to follow the changes in diameter or height of the containers are made by 2 hand wheels that are indexed with digital counters.

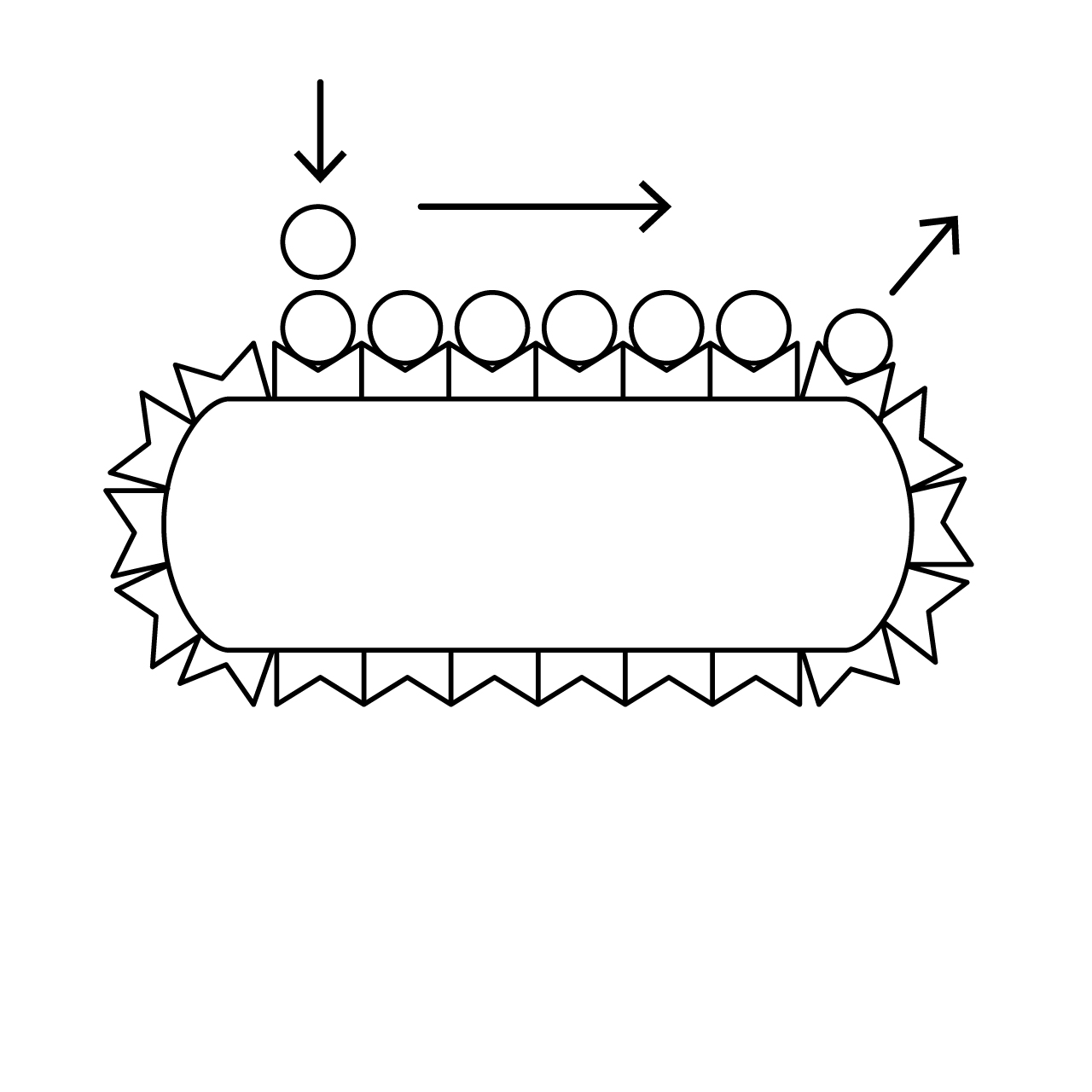

Double walking beam

Round, square or oval containers are moved, clamped and moved again. This system is continuously mechanically adjustable and enables the transport of containers with diameters between 16- 70 mm without format parts. Mechanical settings to follow the change in diameter or height of the containers are made by 3 hand wheels that are indexed with digital counters.

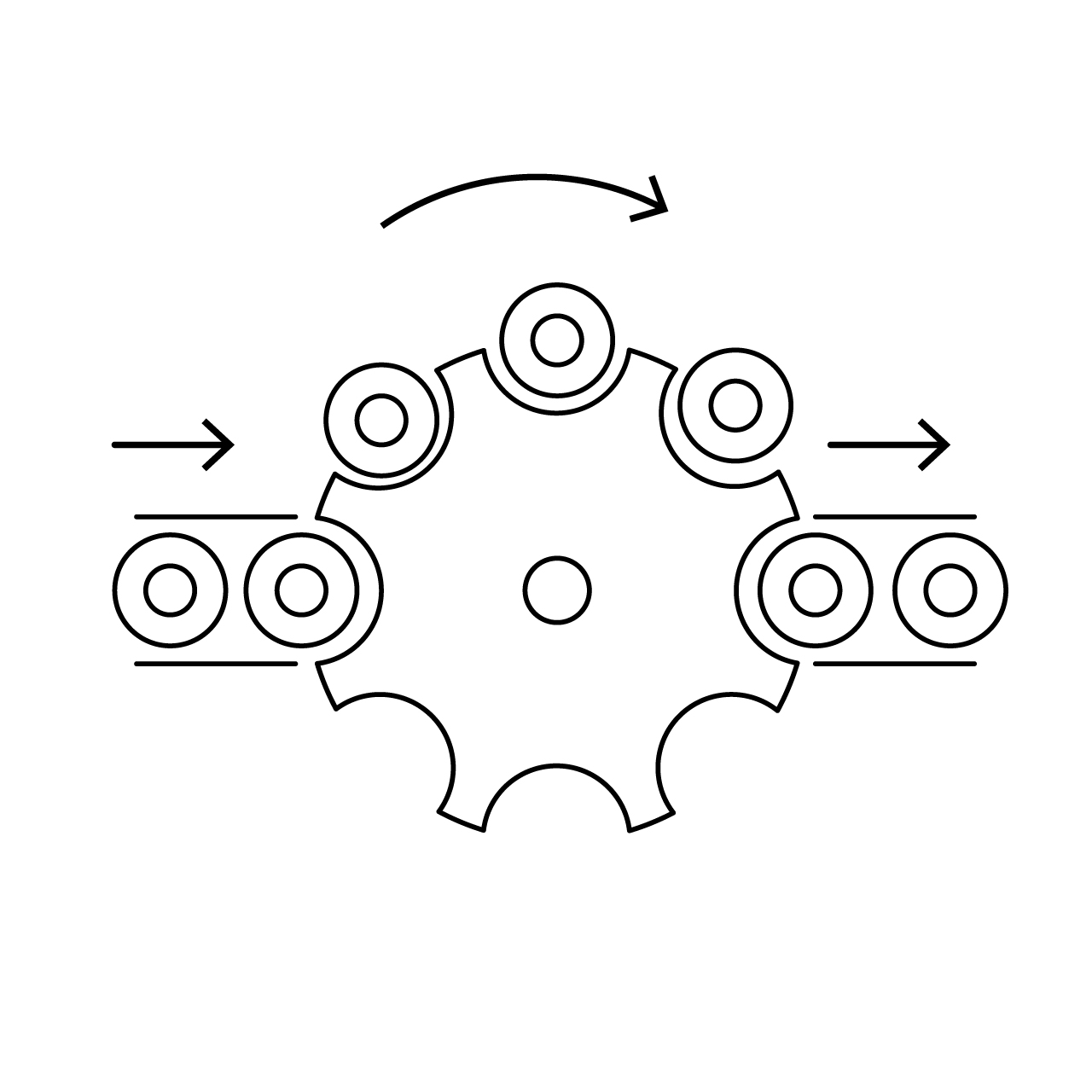

Star wheel

In a starwheel, round, square or oval containers are moved step by step clockwise through the process. This system is useful when only a few different formats shall be run, as the starwheel and the guides are always format parts. Container diameters from 10 mm – 60 mm in a single step, from 10 mm – 40 mm in a double step and from 10 mm – 30 mm in a triple step machine can be treated.

Endless screw

In an endless screw, round, square or oval containers are moved step by step through the process. This system is continuously mechanically adjustable and enables the transport of containers with diameters between 16 mm – 90 mm in a double step and 16 mm – 40 mm in a single step version. The screw is a format part to be changed. Mechanical settings to follow the changes in diameter or height of the containers are made by 2 hand wheels that are indexed with digital counters.

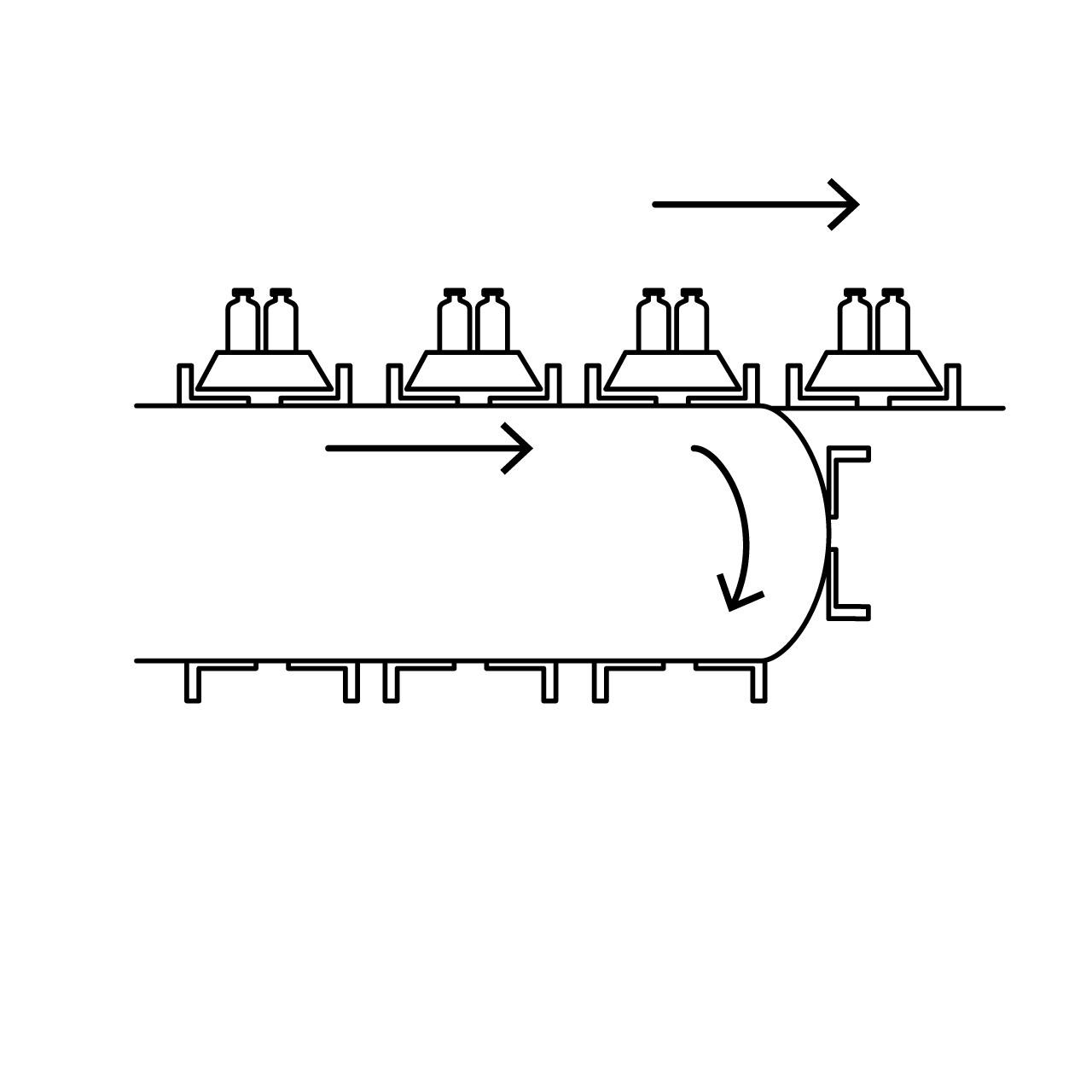

Indexed conveyor belt for blister trays

We dispose of the technology to denest blister trays and load containers, syringes, spatulas, etc. into a blister. Afterwards the blisters are optionally capped and labelled. («Trayloaders»).

Conveyors

Stable containers can be moved by conveyors. The Zellwag machines work with belt or plate chain conveyors. The conveyors are manufactured in a hygienic design and can easily be cleaned.

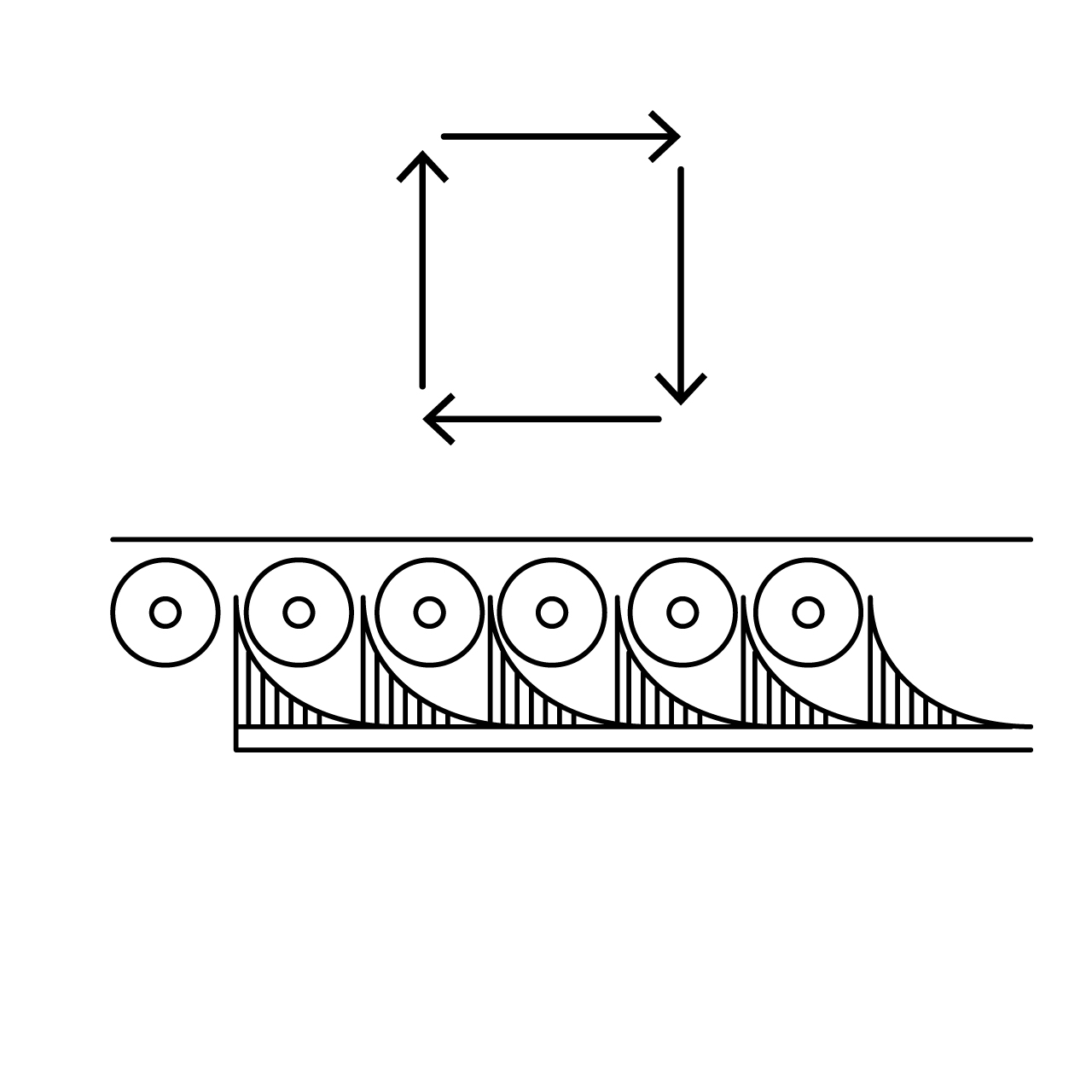

Circulating prism belt

In a circulating prism transport, round, square or oval containers are moved step by step through the process. The containers run automatically from an infeed turntable onto the prism belt. This system is continuously mechanically adjustable and enables the transport of containers with diameters between 16- 55 mm without format parts. Mechanical settings to follow the changes in diameter or height of the containers are made by 2 hand wheels that are indexed with digital counters.