Our commitment to vaccine-supporting industries – Part 2

If you are a business looking to develop new manufacturing or further automate your production and require everything from table-top filling and closing equipment for small-batch production to commercial scale machines, then the swiss machine manufacturer Rychiger Pharmtech AG is on-call to help. Whether it is the manufacturing of sample collection tubes, immunoassay reagent kits, DNA/RNA PCR test kits or sterile vaccine drug manufacturing, our advanced know-how in the pharma, healthcare and IVD sector enables us to supply state-of-the-art cGMP production equipment for the supply of COVID-19 IVD test kits as well as support for vaccine and pharma drug programs around the globe.

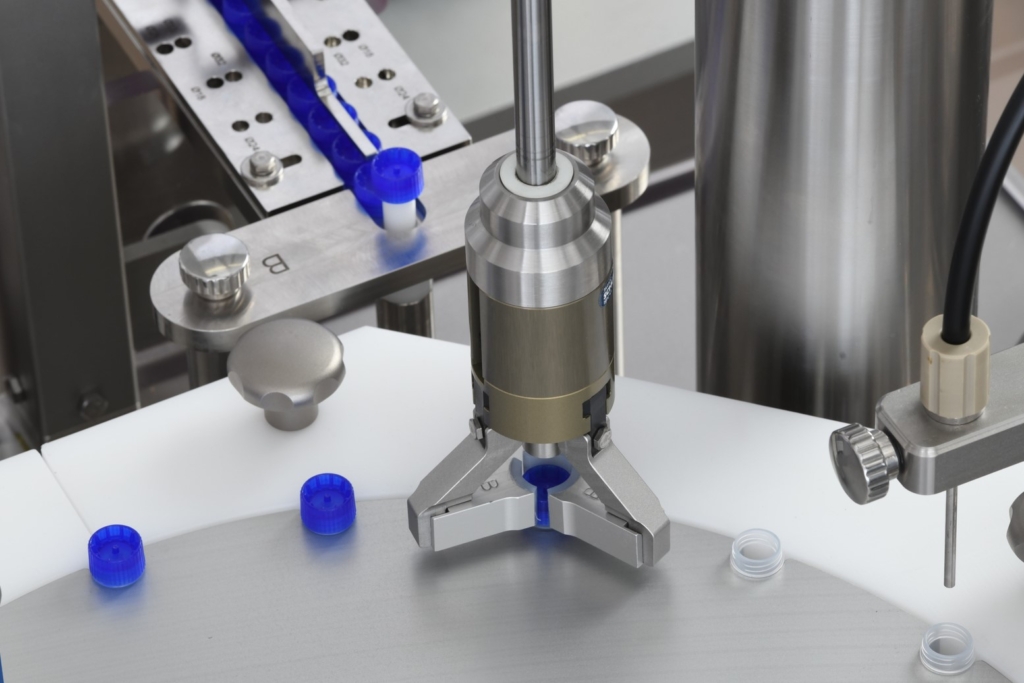

IVD kit Manufacturing: Sample Collection Tubes

The first part to any diagnostic test is always sample collection from saliva, nasal-pharyngeal swabs, blood, amniotic fluid, urine, tissue biopsy collection tubes to faecal swabs. Sample collection and sample preservation is a skilled and increasingly sophisticated part of the clinician’s toolkit. A sample collected in the wrong way or without the appropriate preservation reagent can render precious samples useless or give false results. Often overlooked or considered a Cinderella application, the current pandemic has shown sample collection to be an integral and vital part of the fight against COVID with shortages of collection kits apparent in some areas. Rychiger Pharmatech AG understand this and pay respect to the key processes of sample collection, isolation and preservation. To specifically support IVD research and manufacturing operations, Rychiger Pharmatech has further developed their machine platforms for the scalable manufacturing of a range of sample collection tubes / devices.

Figure 1: Filling and closing for IVD Immunoassay

and PCR reagent kit

Modular Machine Concept

As standard platforms with shorter-lead times for quick delivery and deployment, the modularity of design around a rotary-indexed table allows for the additional feeding of inserts, or swabs either as part of the closure cap such as faecal sampling cups and dip-sticks or as a separate in-feed and can accommodate a variety of cap fittings and closures. Peristaltic or piston pumps can be fitted as standard. With various labelling options, products can be produced ready for downstream packaging activities and are easily installed and deployed into existing or new cGMP IVD production operations.

Figure 2: Integrated cap feeding module

Z-110: Filling, Closing & Labelling Machine

Rychiger Pharmatech machines are specialised to the production of IVD kits with the support of in-house experts in many IVD applications. The Z-110 has been in use for many years and has been adapted for immunoassay and molecular diagnostic reagent tubes filling & closing and increasingly for sample collection, isolation and preservation tubes. It is a rotary-indexing platform with up to 8-stations placed around the star-wheel. The modular design and multiple options for infeed allow the machine to process multi-formats with minimal swop-out parts.

Figure 3: Filling and Closing of sample collection tubes

Integration

Whether it is your first machine foray into fill / finish operations as you scale-up or an established IVD kit manufacturer, Rychiger Pharmatech is ready to support your efforts and value the contribution so many research groups are making around the globe. With our partners in packaging, Rychiger Pharmatech is able to supply and integrate the entire line including top loaders and case packers to reduce lead-times and project management to a minimum and to support quicker delivery and provide a complete life-cycle model for your production line solutions.

Figure 4: Integrated labelling module

Z-110: Technical Data

Output: up to 6000 pieces/h

Filling places: up to 3

Container sizes: up to 1000 ml

Pumps: peristaltic, piston, time/pressure 30yl – 1000ml

Options:

- Vision system: option for microtube cap seals

- Labelling: in-line or off-line options

- In Process Control (IPC): tare and gross weight - 100% or random sampling

Figure 5: Z-110 Filling and Closing machine for sample tubes